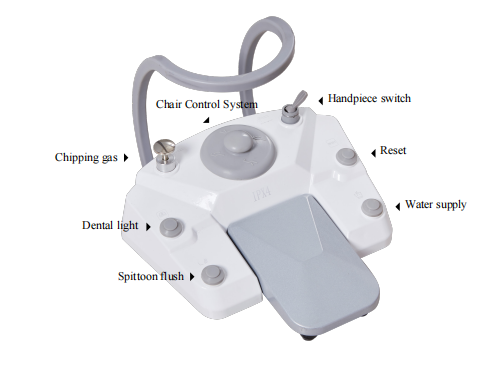

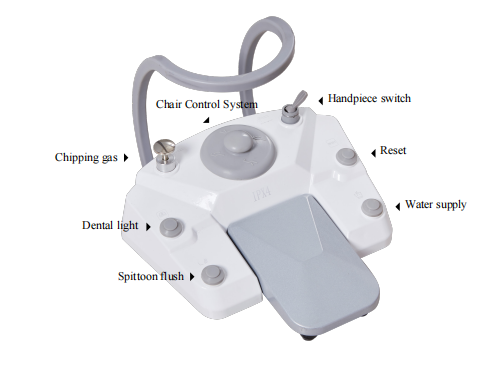

Multifunctional composite foot switch

Integrating the machine-chair interlocking system, chair backrest lift, pitch, one-key sputum flushing, mouthwash, reset, oral light switch, mute and micro-controlling ha ndpiece speed and other functions.

Pedal

Floor-type pedals, when stepping on the pedals, the ankles are forced to relieve certain fatigue. It is easier and less labor-saving to operate continuously for a long time

Base plate

Cast aluminum integrated molding process, light immersion does not rust, light weight but not easy to slide and shift, good stability and durability.